Revolutionize Your Flatbread Production: The Game-Changing Power of Tunnel Ovens

Have you ever wondered how top bakeries consistently produce perfect flatbreads that keep customers coming back? The secret might lie in their kitchen's heart: the tunnel oven.

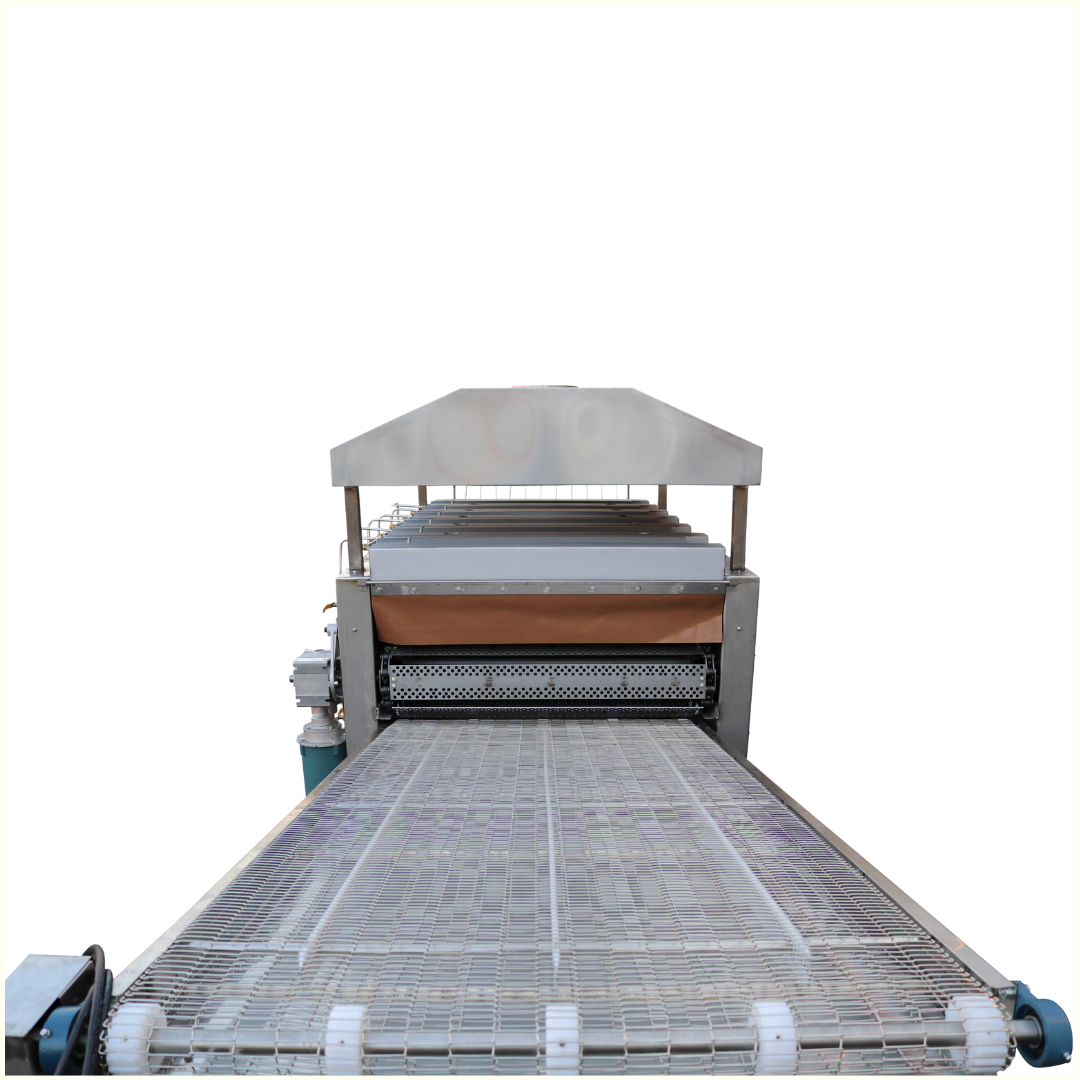

Bakery tunnel ovens are an essential tool when you are looking to enhance your flatbread production. They offer unmatched efficiency and consistent quality, allowing you to create scalable operations that keep pace with growing demand.

Here, we look at the essential role of tunnel ovens and how they can transform flatbread production without sacrificing the quality of your product.

Share this page:

The Future of Bakery Innovation Begins Here

Table of Contents

- The Art of Scaling Artisanal Flatbread Production

- The Evolution of Tunnel Ovens in Bakery Innovation

- Understanding Tunnel Ovens for Flatbreads

- Benefits of Using Tunnel Ovens in Flatbread Production

- Comparing Tunnel Ovens with Traditional Flatbread Baking Methods

- Implementing Tunnel Ovens in Your Flatbread Bakery

- Maintenance and Care for Tunnel Ovens

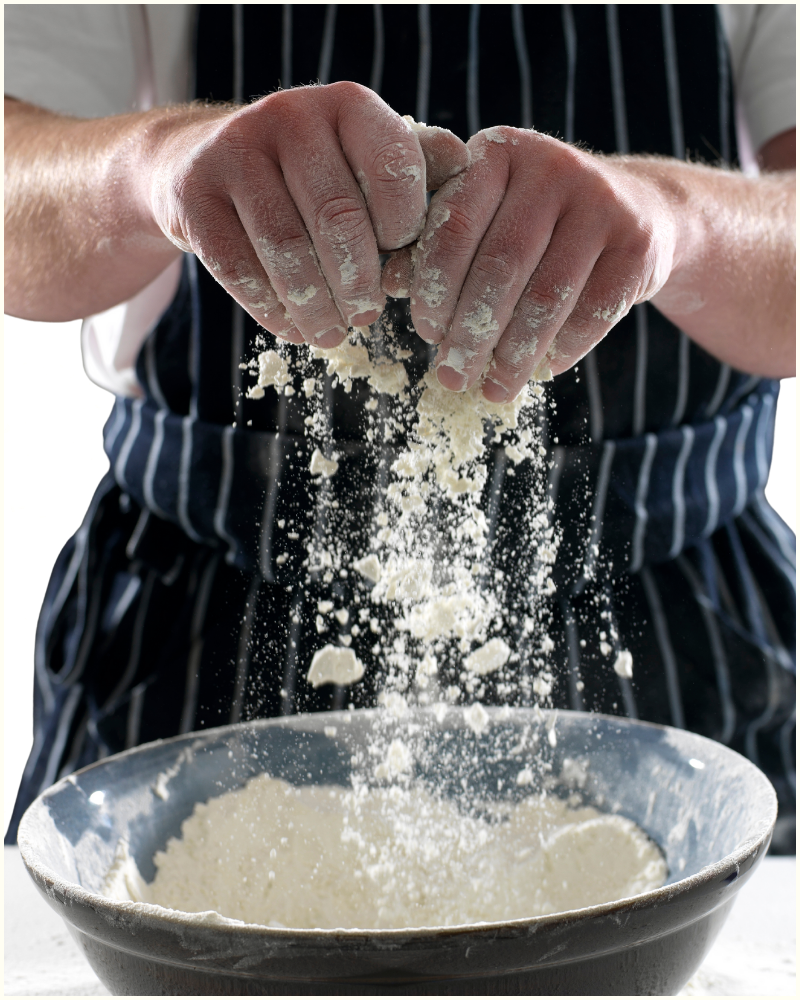

The Art of Scaling Artisanal Flatbread Production

Bakeries face significant hurdles in the intricate art of flatbread making, where tradition meets taste, as they strive to increase production without compromising the authenticity and quality that define their products. Here are the key challenges encountered in the journey of scaling artisanal flatbread production:

Consistency:

The cornerstone of artisanal baking is consistency. Traditional ovens often fall short in uniformly baking each flatbread, leading to variances detracting from the quality and customer experience.

Scaling Production:

Expanding production to meet growing demand poses a dilemma—increasing output without escalating labor costs or diluting the quality that customers expect.

Operational Efficiency:

In an era where sustainability and efficiency are paramount, traditional baking methods' energy consumption and operational costs stand as obstacles to growth and profitability.

Versatility:

Consumer tastes are ever-evolving, demanding a bakery's ability to diversify its flatbread offerings. The challenge lies in adapting baking processes to accommodate a variety of flatbreads without sacrificing quality.

Maintenance and Safety:

As production scales, so does the need for equipment that minimizes downtime due to maintenance and ensures the safety of bakery staff.

Addressing these challenges is crucial for bakeries aiming to thrive in the competitive landscape of flatbread production. The subsequent sections will explore how tunnel ovens offer tailored solutions to overcome these hurdles, paving the way for efficient, scalable, and quality-focused baking operations.

The Evolution of Tunnel Ovens in Bakery Innovation

The journey of tunnel ovens began in the early 20th century. While rudimentary initially, these ovens introduced continuous baking processes, revolutionizing productivity.

Technological advancements over the decades have transformed tunnel ovens into highly efficient, precise baking solutions. Today's models boast features like direct gas-fire and indirect heating, ensuring unparalleled consistency and quality.

With these advancements, tunnel ovens have become the cornerstone of modern bakery operations, redefining flatbread production with enhanced efficiency and scalability.

Understanding Tunnel Ovens for Flatbreads

Tunnel ovens have been used for decades as an affordable solution to increase production in bakeries of all sizes. A tunnel oven leverages technology to produce continuous baking that is ideal for flatbread production. They come in direct gas-fire (DGF) or indirect heating units, allowing you to introduce high-volume pita production to your bakery without interfering with the quality baked goods your customers demand.

Conveyor tunnel ovens enhance productivity without the need to increase labor and reduce labor demands. This advanced bakery equipment is ideal for smaller bakeries sitting on the brink of growth yet unable to invest in new equipment and a larger team.

You can increase productivity and reduce costs with a pita bread tunnel offering excellent potential for return on investment. As a result, you can set your sights on growth whether you require a tandoor tunnel oven, tunnel pizza oven, or pita tunnel oven.

Benefits of Using Tunnel Ovens in Flatbread Production

When it comes to flatbread production, you'll discover many benefits, including:

Labor:

You can expand production without worrying about hiring additional labor to manage operations. The tunnel oven provides continuous production without downtime between batches.

Sizing:

You can tailor your oven size and baking surface width for your bakery space, allowing you to make the most of your square footage while increasing efficiency. As a result, you don't have to move to a larger facility to accommodate increased production. Sizes are available in sizes ranging from 6 to 12-foot lengths and baking surface widths from 24 to 36 inches. Better yet, you have the option to customize your oven.

The perfect bake:

Consistency in quality is essential for baked goods success. A tunnel oven lets you perfect your baking time using custom-made infrared burners. Customers will choose your bakery for beautifully browned flatbreads baked using even heat distribution.

Easy maintenance:

Tunnel ovens are exceptionally durable, using interchangeable burners designed for easy maintenance and repairs to limit downtime.

Versatility:

A choice of baking surfaces allows you to customize your tunnel oven to suit your bakery's production, including:

- Solid carbon steel plates for versatility

- Perforated steel plates for consistent color and texture

- Cordierite baking stones are ideal for pizza or focaccia

Comparing Tunnel Ovens with Traditional Flatbread Baking Methods

Traditional baking methods rely on instinct and sight to determine when the flatbreads are perfectly cooked. However, it takes a dedicated baker and time to achieve that perfection. Also, the number of flatbreads you produce can make it challenging to profit if you have limited space.

Using a tunnel oven allows your experienced bakers to produce the same authentic flatbreads they have always produced despite breaking from traditional methods. Tunnel ovens use technology to improve efficiency and keep up with demand, whether you need 300 or as many as 20,000 pieces per hour.

Your bakers never lose the flavor, texture, or perfect color, as they can try a few "test runs" until they find the correct settings to achieve the perfect flatbread. From there, they can increase the quantities to meet demand.

As a result, you can maintain enough fresh baked goods to keep your customers returning for the traditional, authentic, fresh flatbreads they love.

Implementing Tunnel Ovens in Your Flatbread Bakery

Once you decide it's time to increase production, implementing a tunnel oven into your flatbread bakery is easy:

Choosing Your Tunnel Oven: Key Considerations

The first step is to find a quality tunnel oven that offers the following features:

- Superior insulation to radiate less heat for safety and energy efficiency

- Customization to fit your needs and bakery space

- Consistent, uniform baking with even temperatures to maintain quality

- Adjustable settings and timing to keep up with growing demand

Seamless Installation: Ensuring a Smooth Transition

Easy installation ensures you avoid disruption to your business. You can request installation or do it yourself with a plug-and-go tunnel oven connected to your gas or electrical. When choosing a gas tunnel oven, we recommend having professionals assist to ensure everything is installed safely and to code. A company with installers will ensure everything is working correctly. Depending on the size of your bakery, your oven might need to be disassembled and reassembled.

Beyond the Purchase: Unmatched Support and Service

Find a company offering lifetime support to help your team troubleshoot functional issues as they find the perfect settings and adapt to the technology. They will ensure your flatbread maintains the same quality, texture, and color your customers expect and can even assist in adding menu items using your new equipment.

Maintenance and Care for Tunnel Oven

Once your tunnel oven is up and running, regular cleaning and maintenance are required to optimize performance and expand its life.

Many of our customers have used their tunnel ovens for over a decade by simply ensuring they tend to basic maintenance such as:

- Daily cleaning

- Following the manufacturer's recommendations

- Paying attention to details such as belt tension adjustments, heating elements, and temperature sensors

- Scheduling common repairs, such as replacing or calibrating the sensors, to avoid more costly issues or unexpected downtime in the future

At AMI Equipment, we provide instructions on how to enjoy your tunnel oven for years. Should you experience any issues in the first year, repairs are covered under our warranty for parts and labor. However, we are also here to assist you as long as you own your tunnel oven and are ready with solutions to keep your oven operating efficiently.

Dive Deeper into Bakery Innovation

Curious to learn more about how tunnel ovens can revolutionize your bakery's production process?

You May Also Be Interested

Gain further insights into bakery innovation and compliance with related articles, enriching your understanding of industry standards and equipment excellence.

Share this page:

Site Map

AMI Equipment

Expertly crafted ovens and automation solutions for authentic, traditional flatbread production. Fully customizable and backed by lifetime support.

Follow Us:

Copyright © 2024 AMI Equipment - All Rights Reserved